Project Management&Quality Control

|

Project Management

Language ability: English, French.

For each project, we will assign one project engineer to manage the whole procedure from concept of the very beginning to perfect completion. We have a wonderful project management team, who owns strong engineering background and good at English communication. This helps your project goes smoothly and well under control. We will keep customer updated about detail information of this project by weekly report and updated pictures. It is easy for customer to manage the project at the same time. We will provide high standard of customer service by self-improvement. Just one phone call, or an e-mail, and you'll see we are ready for you anytime.

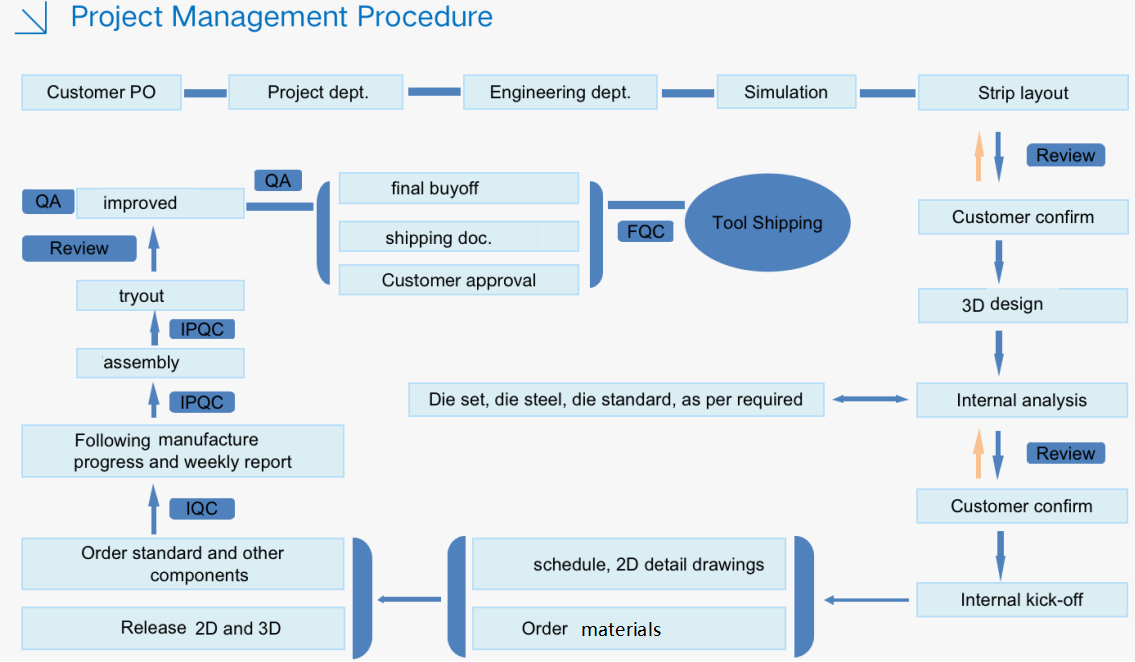

Our project management team always do our best to control your project at every progress:●Kickoff & Review Meeting

Once receiving the formal PO, our project manager will organize a meeting with engineering department, tooling department and quality control department will have a meeting to review customer requirements, special characteristics and history record to optimize the tool design and discuss how to guarantee the critical dimensions, and how to shorten the delivery time and save the cost, meanwhile guarantee high quality of the tools in detailed ways, make the manufacture schedule.

●Design Validation & Machining

Project manager submit the CAE analysis / 3D strip layout / 3D tool design to customers and communicate technical issues with customers. As soon as we receive your approval, we will start to order the material and start to machine. In the tool process, a weekly report with pictures will be sent to our customer on each Monday to help customers track up the project closely.

Quality Control

Quality is the soul of the brand, precision is the basis of the business. In order to ensure precise quality, especially sets up a quality department, which is equipped with 3D measuring instrument, 3D handy scanner projector, height measuring instrument, sclerometer and other precision measuring tools. It strictly implements the ISO 9001 quality system requirements to precisely control all tools and stamping parts. QC inspector precisely test and adequately document the appearance, dimension and hardness of all components to ensure product quality. And then they will record the result to quality control system.

We are committed to our implementation of the zero-defect quality management philosophy. This quality sense has been implemented on each process. We also have very strict supplier verification system, and we execute the regular audit to assure the best quality raw materials. Only qualified suppliers can be our cooperators. With advanced imported measuring devices and efficient control system, the quality of each tool is assured by our professional quality engineers from design to construction to sample to pre-shipment. |

CN

CN